When selecting a dozer blade for your compact excavator or skid steer, it’s important to understand the differences between 4-way and 6-way blades to ensure you choose the best option for your specific needs.

Here are the key considerations to help you decide between a 4-way and a 6-way dozer blade (PAT – Power-Angle-Tilt Blades can come in varying forms, with 6-way functions):

4-Way Dozer Blade

A 4-way dozer blade, also known as an angle blade, offers basic blade movement options that are suitable for many general applications. The four movements include:

- Up and Down: The blade can be raised or lowered to control the depth of cut or fill.

- Angling Left and Right: The blade can pivot left or right, allowing for angled grading or pushing material to one side.

Advantages:

- Simplicity: Easier to operate with fewer controls to manage.

- Cost-Effective: Generally less expensive than a 6-way blade.

- Durability: With fewer moving parts, there is less maintenance and lower risk of mechanical issues.

- Ideal for Basic Tasks: Perfect for straightforward tasks like simple grading, backfilling, and spreading material.

Limitations:

- Limited Versatility: Cannot tilt or perform complex grading operations.

- Less Precision: May not be suitable for tasks requiring fine adjustments and precise control.

6-Way Dozer Blade

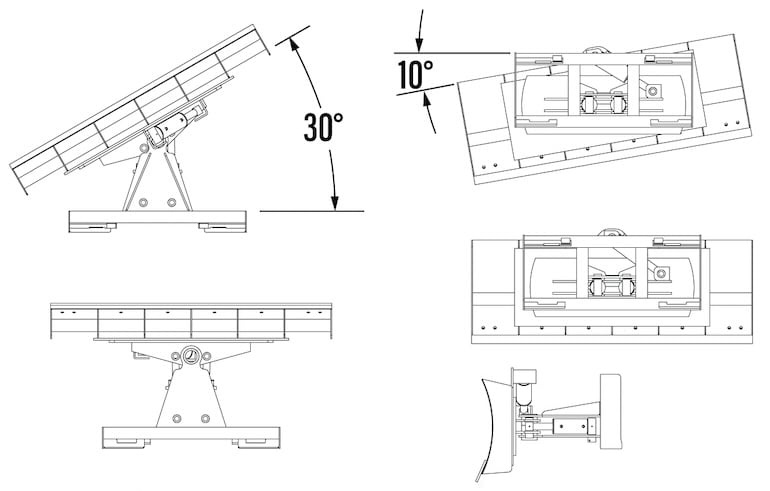

A 6-way dozer blade, also known as a PAT (Power Angle Tilt) blade, offers more advanced blade movement options, making it highly versatile. The six movements include:

- Up and Down: Control the depth of cut or fill.

- Angling Left and Right: Pivot the blade left or right for angled grading.

- Tilting Left and Right: Tilt the blade up or down on either side, enabling more precise contouring and grading.

Advantages:

- Versatility: Capable of performing a wide range of tasks, including complex grading, ditching, and slope work.

- Precision: Offers fine control for detailed work, such as creating precise slopes and contours.

- Efficiency: Reduces the need for multiple passes and adjustments, saving time and labor on the job site.

Limitations:

- Complexity: More controls to manage, which may require more operator skill and training.

- Higher Cost: Typically more expensive than 4-way blades due to the additional functionality and complexity.

- Maintenance: More moving parts can lead to increased maintenance and potential for mechanical issues.

Choosing the Right Blade 4-Way vs 6-Way

Choosing between a 4-way and a 6-way dozer blade depends on your specific project needs, budget, and the skill level of your operators.

By understanding the advantages and limitations of each type, you can make an informed decision that will enhance the efficiency and effectiveness of your work.

Project Requirements:

- Basic Tasks: If your primary tasks involve simple grading, backfilling, or spreading material, a 4-way blade may suffice.

- Complex Tasks: For more detailed work such as fine grading, ditching, and slope work, a 6-way blade is the better choice.

Budget:

- Cost Constraints: If budget is a major concern, a 4-way blade offers a cost-effective solution.

- Investment for Versatility: If you can invest in versatility and efficiency, the higher initial cost of a 6-way PAT blade can pay off in the long run.

Operator Skill Level:

- Ease of Use: For operators with less experience, a 4-way blade is simpler to use.

- Advanced Operation: Skilled operators can take full advantage of the capabilities of a 6-way blade for more precise and complex tasks.

Frequency of Use:

- Occasional Use: For occasional use, a 4-way blade may be more than adequate.

- Frequent Use: For frequent and varied use, the adaptability of a 6-way blade offers greater long-term value.

Selecting the appropriate dozer blade for your tractor or skid steer loader is crucial for optimizing your project’s productivity and efficiency. Our detailed table provides a clear comparison between the 4-way and PAT 6-way dozer blades, focusing on their distinct features and benefits for various applications.

This comparison will help you determine the best blade for your specific project requirements, budget considerations, and operator proficiency.

Whether you need the straightforward functionality of a 4-way blade or the advanced maneuverability of a 6-way blade, this table will guide you in making an informed decision tailored to your equipment and operational needs.

| Feature | 4-Way Dozer Blade | 6-Way Dozer Blade |

|---|---|---|

| Blade Movements | Up, Down, Angle Left, Angle Right | Up, Down, Angle Left, Angle Right, Tilt Left, Tilt Right |

| Versatility | Basic grading and leveling | Advanced grading, ditching, slope work |

| Precision | Limited precision for detailed work | High precision for detailed and complex tasks |

| Ease of Use | Simple controls, easier for less experienced operators | More complex controls, requires skilled operators |

| Cost | Generally less expensive | Higher cost due to additional functionality |

| Maintenance | Fewer moving parts, lower maintenance | More moving parts, higher maintenance |

| Ideal Applications | Simple grading, backfilling, spreading material | Fine grading, contouring, creating slopes and ditches |

| Efficiency | May require more passes for detailed work | Reduces the need for multiple passes, more efficient |

| Operator Skill Level | Suitable for operators with basic skills | Best utilized by skilled operators |

| Durability | High durability due to simpler design | Slightly lower durability due to more complex mechanisms |

| Budget Consideration | Ideal for budget-conscious projects | Better for projects where versatility and efficiency are key |

| Typical Usage Frequency | Occasional or simple tasks | Frequent and varied tasks |

This table provides a clear comparison between the 4-way and 6-way dozer blades (PAT), helping you to choose the right blade based on your project requirements, budget, and operator skills.